LASERFIN® - Finned Tubes

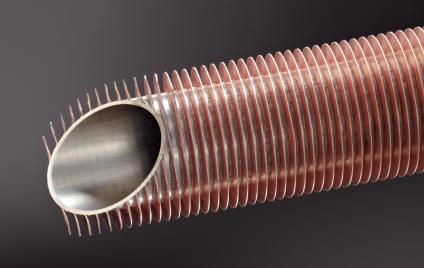

Schmöle is the inventor of the innovative Laserfin® technology. The patented laser welding process enables the production of completely individual, 100% gap-free stainless steel finned tubes for every requirement.

Based on the modular principle, we select the appropriate standard and special stainless steel for tube and fin in dialogue with our customers, define flexible fin heights and distances and design finned tubes with a long service life that are specially tailored to your requirements. Additional details such as recesses and the ability to fold over individual fins make our Laserfin® tubes the most flexible family of finned tubes in the world. Different material combinations are available, for example stainless steel tubes with copper or aluminum fins are possible, up to titanium materials.

Benefits of the original Laserfin® technology

- 100 % flexibility

freely combinable of tube and fin material - 100 % gap free because of 100 % laser welding of fin and tube

- Increased heat transfer - high performance

because of 100 % laser welding of fin and tube - High corrosion resistance against aggressive media

because of flexible use of different material combinations - High reliability with highest output

because of inseparable 100% laser welding - Easy shaping of the finned tubes

because of simple bending and coiling of the finned tubes - Compact heat exchanger design

because of high outside heat surface of the finned tubes - Low heat exchanger weight

because of reduced tube numbers - Standard tube materials

Stainless steel 1.4301 (TP304), 1.4404 (TP316L), 1.4571 (TP316Ti) and more materials on request - Standard fin materials Stainless steel 1.4301 (TP304), 1.4404 (TP316L), 1.4571 (TP316Ti) Copper (Cu-DHP), Aluminium (Al99,5 EN AW-1050A) and more materials on request

Fields of application of Laserfin® finned tubes

Original Laserfin® tubes are manufactured exclusively by Schmöle in Germany. They are suitable for all types of heat exchangers for cooling and heating gases and liquids - especially for the following fields of application:

Heating Industry

- Primary heat exchanger in gas- and oil condensing heating boilers

- Direct fired primary heat exchanger for gas-condensing tankless

instantaneous water heating boilers to heat up tap water

- Secondary heat exchanger for gas- and oil condensing heating boilers to pre-heat heating water - Economizer

- Secondary heat exchanger for micro CHP systems - Economiser

Heatrecovery

- Flue gas cooler

- Heat exchanger for the bakery industry to pre-heat heating

water - Economizer

Mechanical and plant engineering

- Heat exchangers for gas cooling of industrial furnaces

- Heat exchangers for tank heating

- Oil coolers for vacuum plants, ship plants, pumps etc.

- Heat exchangers for oil preheating or cooling

Power plants

- Cooling towers or cooling water recooling plants with dry or wet operation

- Sodium coolers for Fast Breeder power plants

- Flue gas cooling and heating in flue gas desulfurisation scrubbers (FGD) and nitrogen removing plants (DENOX)

Chemical industry

- Heat exchangers of all kinds for cooling and heating of liquids and gases

- Heat exchangers for nitric acid (HNO3) plants, e.g. for the fertilizer

Innovatives Engineering made in Germany

With the production of 10,000,000 tubes and 200,000 finned tube coils to date, our original Laserfin® process is a unique success story. We use a laser beam to weld the fin onto the tube under protective gas for a 100% gap-free result. The fins are inseparably connected to the tube, ensure higher heat transfer and prevent crevice corrosion. Our innovative technology convinces with unlimited possibilities.

As the only manufacturer in the world, we combine all possible non-ferrous metals in the original Laserfin® process, thus ensuring maximum individuality for your finned tube solutions. Schmöle is the inventor of the innovative Laserfin® technology, which was first used in the 1980s. Since then we have been continuously developing it and are currently using the 5th laser generation.

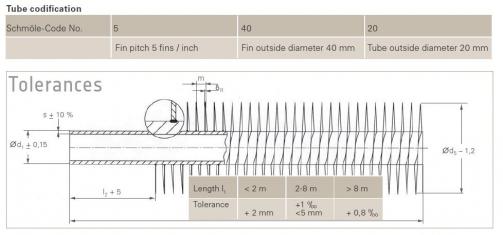

Overview of Laserfin® standard dimensions