OIL COOLER HEAT EXCHANGER

Efficient Oil Cooler Heat Exchangers from Schmöle

Compact, Powerful, and Versatile

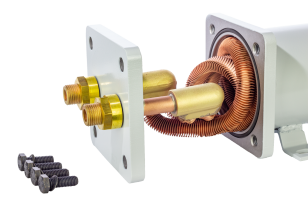

Schmöle oil cooler heat exchangers are perfectly suited for cooling/heating hydraulic oil, emulsion and water from closed oil cooler circuits. By using high-performance finned tubes, oil cooler heat exchangers are particularly compact and powerful, as large heat exchange surfaces can be accommodated in the smallest possible space. The oil cooler heat exchangers consist of a cylindrical steel housing in which a finned tube heat exchanger made of copper or copper nickel is installed.

Benefits of LOK oil cooler heat exchangers

- Easy to assemble and maintain

- High temperature capable

- Low cooling water requirement

- Seawater variants and custom designs available

- Standard designs available at short notice

- Special designs according specifications

- Also available as tank-mounted cooler

- In-house production of housing and finned coils

- Corrosion resistant

- easy cleaning of the heat exchanger

- Scope for expandability of the coil inside.

- Highly effective cooler with finned tubes and spiral internal webs.

Fields of application

Oil cooler finned coil heat exchanger according to customer's specification are especially used in the following equipment:

- Plastic injection molding machines

- Plastic extruder plants

- Hydraulic plants, presses

- Machine tools

- Clutches and gearboxes

- Compressors and pumps

- Temperature control units

- Waste heat recovery

Customized finned tube heat exchanger

Together with its customers, Schmöle develops customized solutions for heat transfer between media such as operating fluids, products or gaseous material flows and the associated liquid or gaseous cooling and heating media.

To increase the transferable heat output, to adapt the geometry to the available installation space and to increase the availability and service life of the heat exchanger, Schmöle relies on the use of its high-performance finned tubes.

Examples include:

- Temperature control of coolants and oil in machine tools

- Heat exchangers for compressors

- Temperature control of erosion fluids

- Oil cooling in transmission housings for automotive engineering

Materials

With its technical equipment and know-how, Schmöle is able to process all metallic materials. In addition to aluminum, copper and copper alloys, Schmöle also manufactures heat exchangers from corrosion-resistant materials such as stainless steels, nickel-based alloys and titanium. These are used in cases of increased corrosion stress due to the use of media such as surface water, seawater and water from closed circuits.

Approval

LOK oil coolers coil heat exchangers are considered pressure vessels in the sense of the Pressure Vessel Ordinance. The HP 0 approval required for manufacture is available for all designs and capacity sizes.

Adaptation to the available installation space

The integration of heat exchangers for oils, cooling water or other operating fluids in housings or vessels is often made difficult by the limited installation space available. Together with its customers, Schmöle develops geometrically optimized heat exchangers depending on the media to be tempered.